How Mitchell Wines is managing electricity costs by controlling annual load and remaining a small business customer.

Mitchell Wines is a third-generation family winery producing red and white wines in the Clare Valley Region of South Australia. As the winery has grown, so have its electricity bills. Mitchell Wines is now taking control of their electricity consumption.

Over 2018-19, Mitchell Wines noted that the winery had consumed 158MWh of electricity and that exceeding 160MWh per year would move the business to a large business tariff.

Over 2018-19, Mitchell Wines noted that the winery had consumed 158MWh of electricity and that exceeding 160MWh per year would move the business to a large business tariff.

Mitchell Wines participated in the Winery Energy Demand Management Program, funded

by Green Industries South Australia (GISA) and managed by the South Australian Wine Industry Association (SAWIA). Through the program energy consultants 2XE were engaged to find out how changing tariffs would impact their electricity bill.

In South Australia, the quantity of electricity you use per year will govern which tariff you are allocated by SA Power Networks (SAPN) – either a large or small business tariff (Figure 1).

Small business tariffs are charged based on electricity consumption (kWh). Large business tariffs are charged based on both consumption (kWh) and demand (kVA).

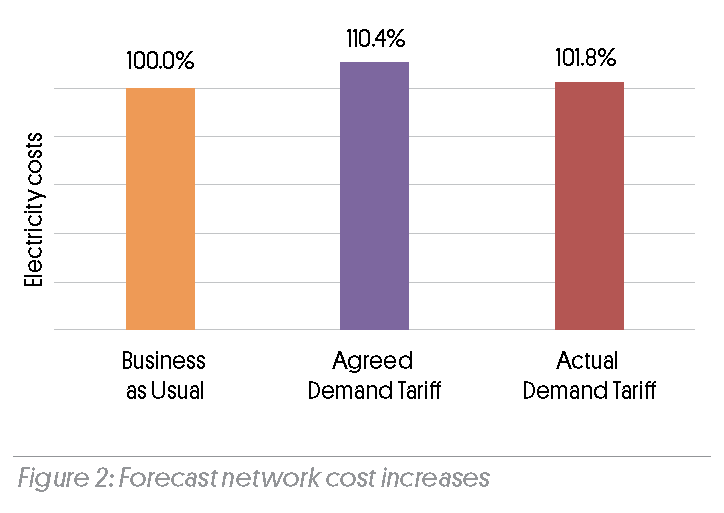

An analysis to understand the impact of Mitchell Wines moving onto a large business tariff found that Mitchell Wines’ electricity costs would increase by 10.4% p.a. if they transitioned to a large business tariff, with an agreed demand. However, Mitchell Wines could reduce this increase to only 1.8% p.a. if they transitioned to a large business tariff, with an actual demand.

This new system will reduce Mitchell Wines’ annual electricity consumption by ~20%, keeping the winery well below the small business consumption threshold.

Modelling of solar PV generation and Mitchell Wines’ electricity use indicated that the 100kW solar system is oversized. A proportion of electricity generated by the solar PV system will be exported back to the grid outside of vintage.

Mitchell Wines is not paid for the electricity it sends back into the grid. It is now a priority for Mitchell Wines to negotiate a feed-in-tariff with an electricity retailer to further reduce electricity bills.

Another opportunity to reduce the winery’s electricity consumption is to replace all metal halide high bay lights (Figure 4), with LED alternatives.

Another opportunity to reduce the winery’s electricity consumption is to replace all metal halide high bay lights (Figure 4), with LED alternatives.

The South Australian government currently supports the upgrade of high bay lights to LEDs

through their Retailer Energy Efficiency Scheme (REES). The upgrade is undertaken through Trade Services South Australia (TSSA) and up to 19 high bay lights can be replaced for about the same cost of scissor lift hire. For more information and conditions of this offer, head to the TSSA website.

The replacement of all winery high bay lights to LED alternatives will reduce electricity consumption by 6.6% and costs by 5.1%.

The third way that Mitchell Wines can reduce electricity consumption is by changing how it uses an on-site refrigeration system (Figure 5). By shifting refrigeration loading to overnight during vintage, Mitchell Wines can make the most of cheap off-peak power and high refrigeration efficiency due to cooler ambient air. This is expected to reduce the chiller’s vintage energy use by 5-10% and provide a 4.4% annual energy cost saving.

The third way that Mitchell Wines can reduce electricity consumption is by changing how it uses an on-site refrigeration system (Figure 5). By shifting refrigeration loading to overnight during vintage, Mitchell Wines can make the most of cheap off-peak power and high refrigeration efficiency due to cooler ambient air. This is expected to reduce the chiller’s vintage energy use by 5-10% and provide a 4.4% annual energy cost saving.

The potential savings of these actions are:

Additional Solar PV (40kW)

- Expected energy savings 35 MWh p.a.

- Expected cost savings $13,600 p.a.

- Return on investment < 5 year

- GHG emissions savings 25.2 tCO2e

- KVA load eliminated from grid 8-12 KVA

LED High Bays

- Expected energy savings 10.3 MWh p.a.

- Expected cost savings $2,900 p.a.

- Return on investment < 1 year

- GHG emissions savings 5.3 tCO2e

- KVA load eliminated from grid 15 KVA

Refrigeration

- Expected energy savings 4.1 MWh p.a.

- Expected cost savings $2,100 p.a.

- Return on investment < 1 year

- GHG emissions savings 2.1 tCO2e

- Max KVA load eliminated from grid 28 KVA